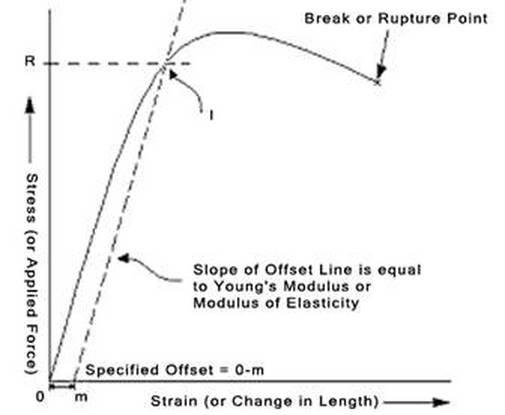

So, to determine if the equipment can bend your steel section, you need to calculate the section modulus mathematically or by referring to engineering tables. A three-roll section bender can be designed to bend steel with section modulus between 0.4 to 500 in3. All bending equipment have section modulus ratings. You need to divide the maximum bending moment by the section modulus to get the bending stress and then compare the bending stress to the allowable tensile stress to see if the steel can take that much moment. It provides a parameter for the development of dynamic building materials. The calculation from Modulus of Rupture helps us to build structural elements such as beams, cantilevers, shafts, etc. If your steel has a high section modulus it will be harder to bend and can withstand a high moment without having high bending stress. The calculation of the modulus of rupture is considered important for construction equipment for the following reasons. A rectangular piece of testing material is laid on two supporting pins. In the following, another way to evaluate Young’s modulus is described - the three-point flexure test. In simple terms, the section modulus is the ratio of bending moment to bending stress for steel. The Young’s modulus can be evaluated with different such as the commonly used tension test. The bending moment that it takes to yield that section equals the section modulus times the yield strength. In the case for bending a steel section it is important to calculate ‘S’ by taking the moment of inertia of the area of the cross section of a structural member – divided by the distance from the neutral axis to the furthest point of the steel section. Stress E x Strain So stress will be higher if E is higher. In flexure, if the two materials are at the same distance from the N.A., they will have the same strain at that point because both materials share the same strain diagram. There are two types of section moduli, the elastic section modulus (S) and the plastic section modulus (Z). In flexure the strains are the same as in a homogeneous section, i.e. Without accounting for the true geometry, substantial errors in the calculated modulus can result. Section modulus is a geometric property for a given cross-section used in the design of flexural members. For diaphyses, one can calculate an effective elastic modulus of the tissue if the true cross-sectional geometry and its variation along the diaphyseal axis are included in the calculations. Bending a steel section that has a larger section modulus than another will be stronger and harder to bend. Section modulus is the direct measure of the strength of the steel. Straight lines in the plate that were originally vertical remain straight but become inclined therefore the intensity of either principal stress at points on any such line is proportional to the distance from the middle surface, and the maximum stresses occur at the outer surfaces of the plate.To determine if a steel section can be curved you need to first determine its section modulus and then see if you have the correct bending equipment. The middle surface (halfway between top and bottom surfaces) remains unstressed at other points there are biaxial stresses in the plane of the plate.

#Calculating flexture modulus full

Please note that most of the calculators do require a premium membership for full functionality.įlat plate behavior: The plate deflects. Many of the stress and deflection equations and calculators referenced from Roark's Formulas for Stress and Strain. Flat Plates Stress, Deflection Equations and Calculatorsįlat Plates Stress, Deflection Equations and Calculators: The follow web pages contain engineering design calculators that will determine the amount of deflection and stress a flat plate of known thickness will deflect under the specified load and distribution. flexural strain 6deflectionthickness/ (span2) I haven't gone to the ASTM D790 method to check the formula, but lets assume you have it right for a three point bend.

0 kommentar(er)

0 kommentar(er)